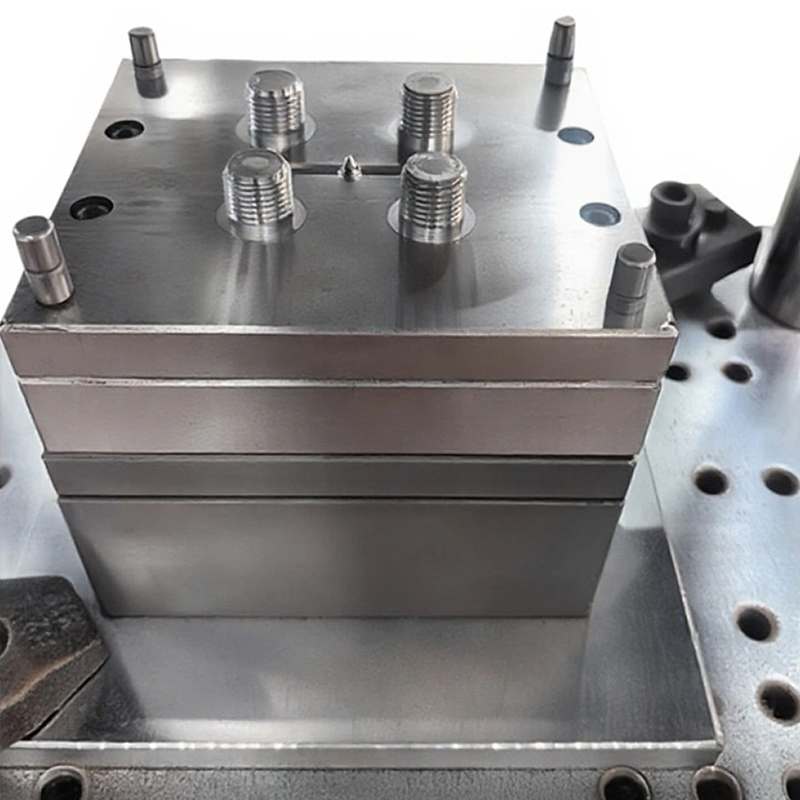

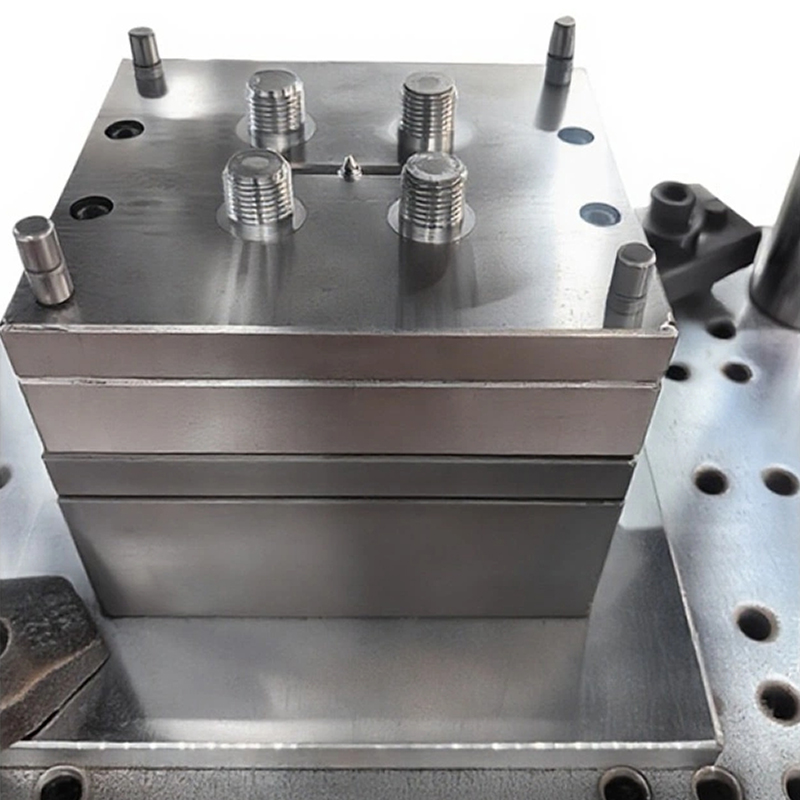

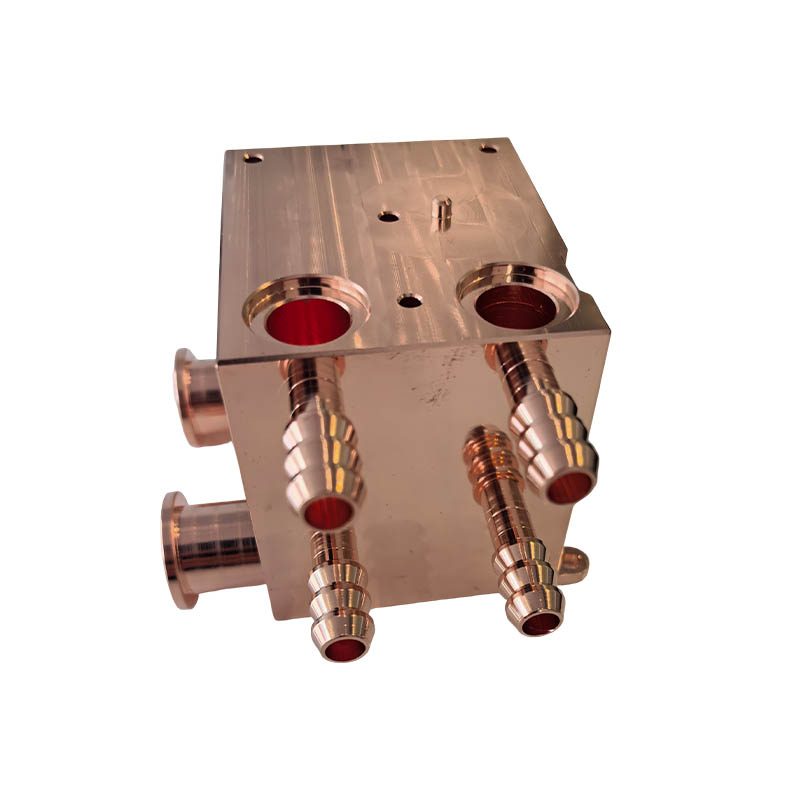

In the process of ABS plastic housing mold customization, the design of the mold venting system is a key aspect to ensure molding quality.

- +86-19925146915

- 417536840@qq.com

- Factory Building 401, Building 23, Fengye 5th Road, Fenghuang, Fuyong, Bao'an District, Shenzhen City, Guangdong Province